How we do It?

At Carbonetics we offer a wide range of unique services from:

- Reverse Engineering

- FEA Design Optimization

- 3D modeling

- CFD simulation

- Rapid prototyping

Our engineering experts work closely with our customers for customized solutions

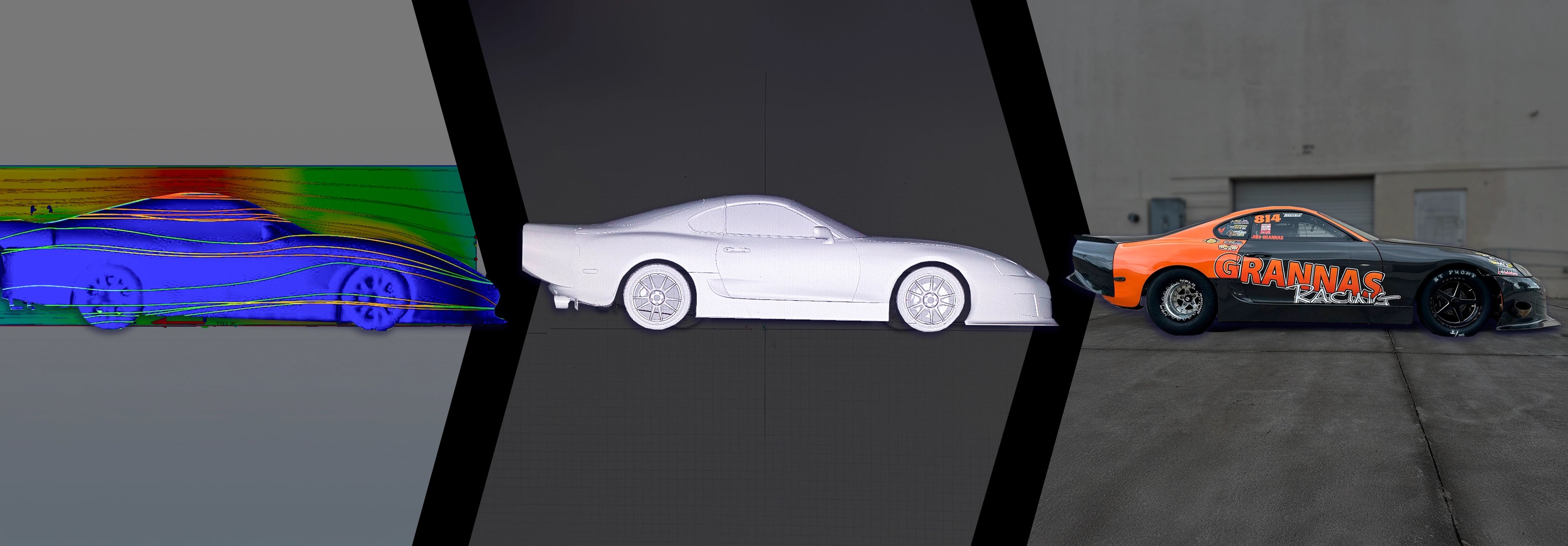

Reconstruction of components

We utilize reverse engineering techniques to reconstruct complex components and systems from limited data or disassembled parts

CFD simulation & FEA design optimization

By performing stress analyses we identify high-stress areas, simulating the deflection of components and deformation patterns, and improve them reducing weight and increasing durability

Rapid Prototyping

We utilize high-precision 3D printers to rapidly develop customized, functional prototypes for testing, ensuring safety and performance, and enhancing product designs prior to manufacturing.

Computer Assisted Manufacturing

3D printing & Resin printing

PRODUCT DEVELOPMENT SERVICES

At the core of our product development studio lies a relentless commitment to innovation, precision, and excellence.

New project in mind?

Why choose our rapid prototyping?

Stress-tested under simulated engine, suspension & drivetrain loads Heat, vibration, and fatigue resistance verified Safety-certified for performance applications

Can’t find the part you need?

We rebuild it with precision. Component reconstruction

Engineered for Perfection

Our methods involve reverse engineering to precisely and reliably reconstruct complex car components and systems. Even with limited data, discontinued parts, or disassembled systems, our advanced techniques restore functionality to its original state.

Why choose component reconstruction with us?

- OEM-Level Accuracy and meticulously restored to exact specifications.

- Experience in Hard-to-Find & Discontinued Parts. No more dead ends in your repair projects.

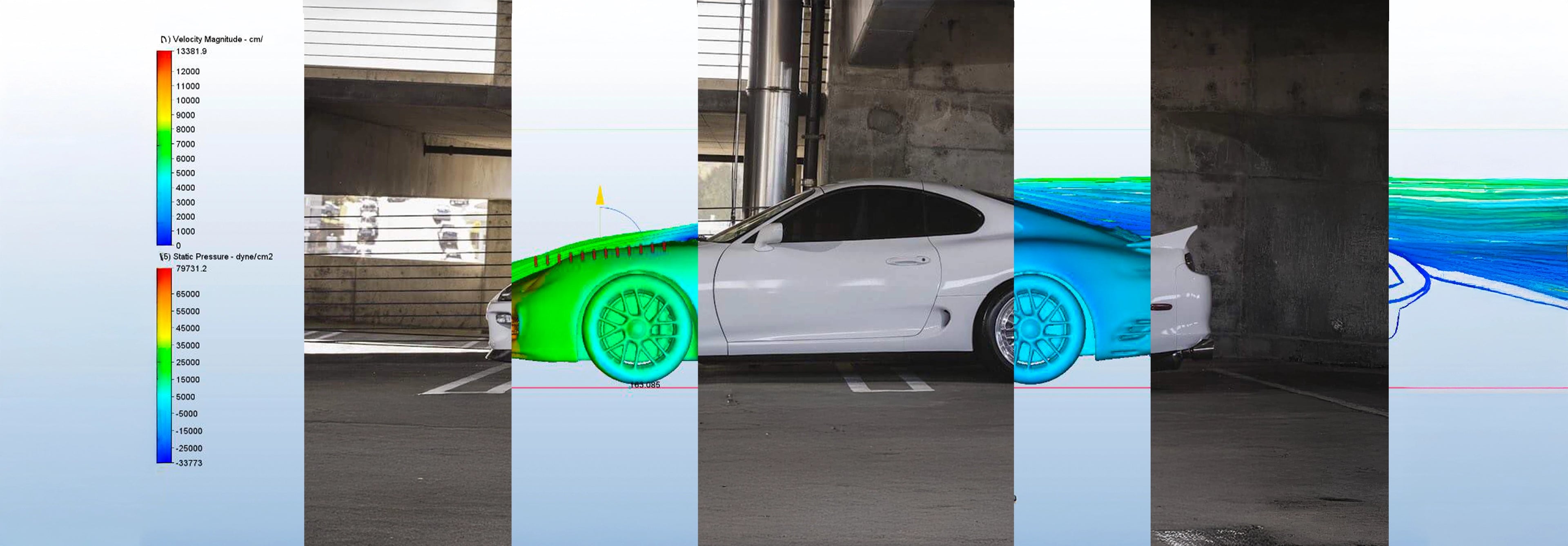

Advanced Component Analysis & Design

Smarter, stronger, more affordable

Why settle for failure-prone parts? Our engineering team analyzes, optimizes, and redesigns components to boost performance, extend lifespan, and cut costs.

How we enhance your car parts?

We diagnose part failures and engineer durable solutions by upgrading performance for better efficiency, strength, and reliability. Optimized designs lead to long-lasting components, and we ensure precision testing, so they fit and function like OEM or better.

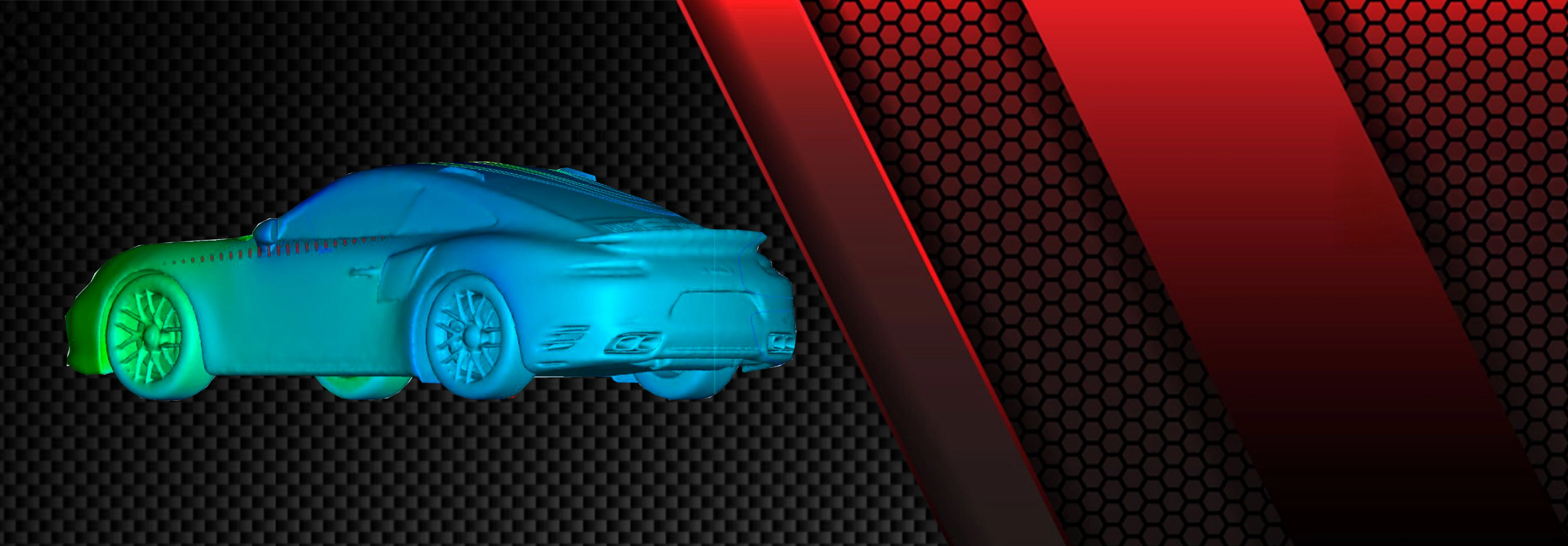

3D Modeling & Prototyping

Perfection in your car parts before production

Why risk fit and function? Our advanced 3D modeling brings your custom car parts to life digitally, before cutting metal.

How we do our 3D process?

- Hyper-Accurate Digital Prototypes – Tested in virtual environments to eliminate real-world failures

- Seamless Manufacturing Transition – Files ready for CNC, 3D printing or tooling

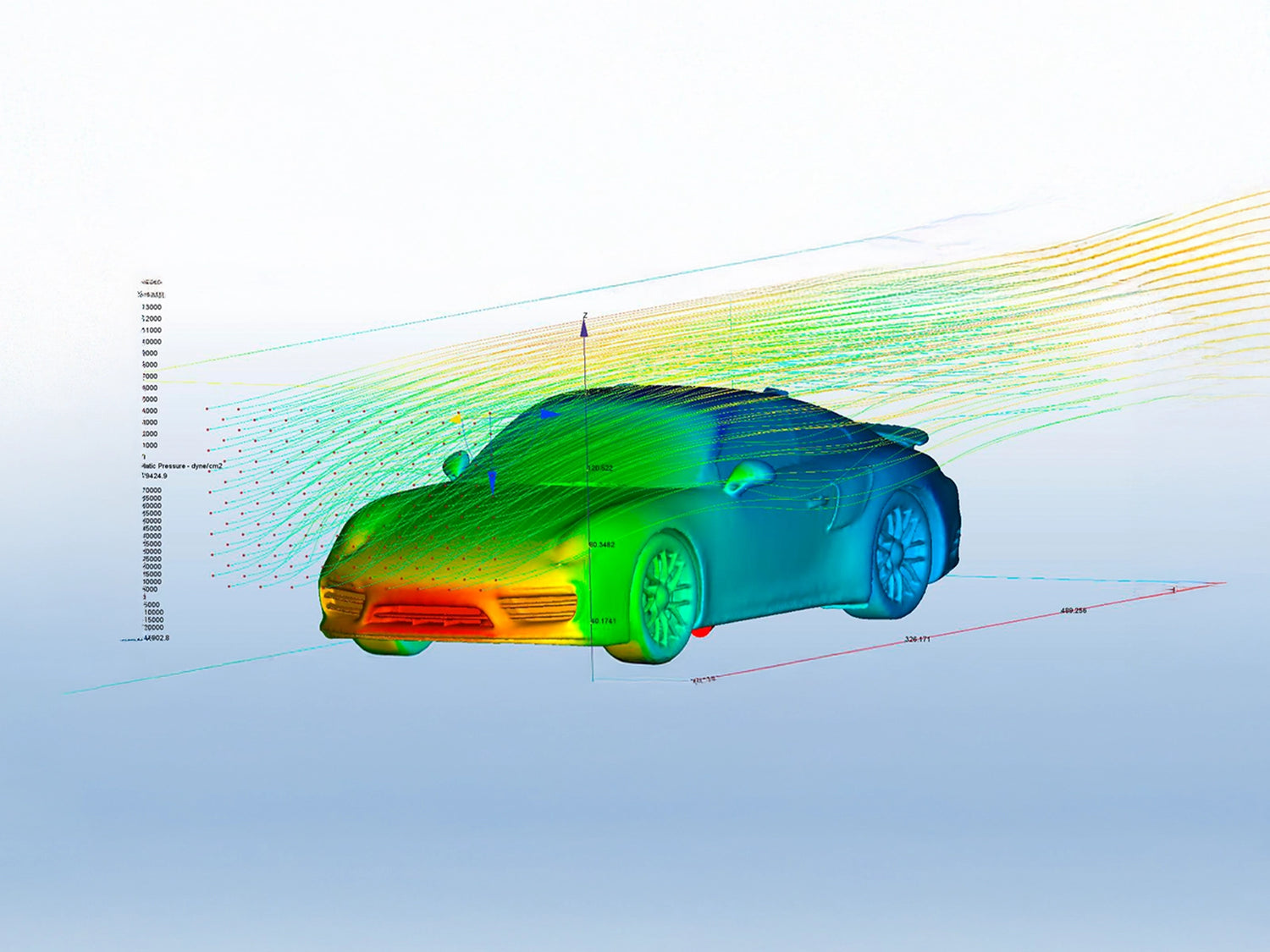

Fluid Simulation

Optimize your vehicle’s Flow Temparature and Pressure

Simulation Services:

Our CFD simulations reveal how your pression, air intake, and exhaust systems behave – before you install a single part.

In-depth analysis allows you to make informed decisions for performance.

Why risk overheating, pressure failures, or inefficient flow?

Our comprehensive fluid dynamics analysis enhances flow circulation for superior performance while eliminating heating and parts deflection.

We specialize in thermal mapping to identify and predict hot spots optimizing cooling for peak performance.

Additionally, we conduct pressure distribution modeling to balance exhaust backpressure for optimal scavenging and simulate intake systems to achieve ideal airflow and fluid behavior in components and systems.

FEA Design Optimization

Our FEA simulations demonstrate performance of your components under real-world stresses prior to use

Our engineering builds stronger, lighter & smarter automotive components.

-

Stress Analysis

- Pinpoint failure-prone areas in suspensions, chassis, and drivetrain components

- Redesign weak points before manufacturing

-

Deflection Modeling

- Bending behavior in structure components

- Optimize stiffness for handling characteristics

-

Weight & Strength Optimization

- Achieve race-grade strength without unnecessary mass

- Perfect material selection for each application

RAPID PROTOTYPING

From concept to high-performance parts in record time

We quickly transform concepts into tangible models by using high- precision 3D printers accelerating the development process while maintaining exceptional accuracy and quality.

We perform thorough testing and validation of our prototypes to ensure their safety and performance.

Computer-assisted manufacturing (CAM)

Laser-sharp precision

Why settle for generic, mass-produced parts?

Our 3D printing, prototypes, tooling, molds, or end-used parts delivers ultra-precise, high-quality components—cut, shaped, and customized exactly to your specs.

We were built for automotive demands with high-strength materials and lightweight solutions only.

Custom braking systems engineered for sports and armor

Top faster. Stay in control.

Our braking systems deliver unmatched stopping power, heat resistance, and durability whether you're pushing limits on the track or navigating high-risk environments.

Why choose our custom braking solutions?

We craft bespoke braking systems for sports cars and armored SUVs, precisely engineered to meet each client’s unique specifications and preferences.

Our unwavering commitment to quality is evident in every component, backed by extensive testing and validation to guarantee exceptional safety and performance

CORPORATE SOUVENIRS THAT ELEVATE YOUR BRAND

Our signature Carbon Hat redefines premium branding, merging cutting-edge materials with unparalleled craftsmanship to create a symbol of prestige.

Interested in corporate souvenirs?

- Fully Customizable – Laser-engraved logos, bespoke color finishes, and tailored fits

- More Than a Gift – A Conversation Starter – Reinvents how clients perceive your brand